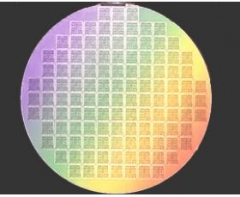

Os produtos modelo de pam-xiamen consistem em camadas cristalinas de nitreto de gálio (gan), nitreto de alumínio (aln), nitreto de alumínio e gálio (algan) e nitreto de indio e gálio (ingan), que são depositados em substratos de safira, O carboneto de silício ou os produtos de modelo de silicon.pam-xiamen permitem 20-50% de tempos de ciclo de epita8

pam-xiamen estabeleceu a tecnologia de fabricação de bolacha de substrato de gancho independente (galão de nitreto), que é para uhb-led e ld. cultivado por tecnologia de epitaxia em fase de vapor de hidreto (hvpe), nosso substrato de ganhado tem baixa densidade de defeito.

Pwam desenvolve e fabrica substratos semicondutores compostos - cristal de arsenieto de gálio e wafer.we usamos tecnologia avançada de crescimento de cristais, tecnologia de processamento de gradiente vertical (vgf) e wafer de gaas, estabeleceu uma linha de produção de crescimento de cristal, corte, moagem para processamento de polimento e construí8

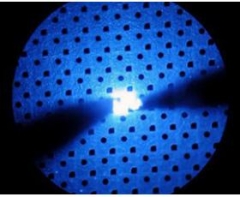

nós fornecemos epitaxia sica customizada de película fina (carboneto de silício) em substratos de 6h ou 4h para o desenvolvimento de dispositivos de carboneto de silício. A bolacha sic epi é usada principalmente para diodos schottky, transistores de efeito de campo semicondutor de óxido de metal, transistores de efeito de campo de junção, transisto8

pam-xiamen oferece wafers de carboneto de silício semicondutor, 6h sic e 4h sic em diferentes graus de qualidade para pesquisador e fabricantes da indústria. Desenvolvemos tecnologia de crescimento de cristal sic e tecnologia de processamento de bolacha de cristal sic, estabeleceu uma linha de produção para o substrato Sic do fabricante, que é apli8

A bolacha epitaxial conduzida a base de gancho pam-xiamen (nitruro de gálio) é para diodos emissores de luz azul e verde de alto brilho (led) e diodos laser (ld).

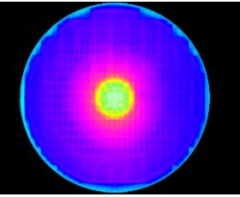

Os transdutores de nitrogênio de gálio (gan) (transistores de alta mobilidade de elétrons) são a próxima geração de tecnologia de transistores de potência rf. Com a tecnologia gan, Pam-xiamen agora oferece alpina epi wafer em safira ou silício e algan / gan em modelo de safira .

Você pode obter o nosso serviço de tecnologia gratuita do inquérito para depois do serviço, com base no nosso Mais de 25 experiências na linha de semicondutores.

nosso objetivo é atender a todos os seus requisitos, não importa quão pequenas encomendas e quão difíceis questões podem ser, para manter um crescimento sustentado e lucrativo para cada cliente através de nossos produtos qualificados e atendimento satisfatório.

Com mais de 25 + anos experiências no campo composto de materiais semicondutores e negócios de exportação, nossa equipe pode assegurar-lhe que podemos entender seus requisitos e lidar com o seu projeto profissionalmente.

A qualidade é nossa primeira prioridade. pam-xiamen foi iso9001: 2008 , possui e compartilha quatro fábricas modernas que podem fornecer uma grande variedade de produtos qualificados para atender às diferentes necessidades de nossos clientes, e cada ordem deve ser tratada através de nosso rigoroso s8

Os cristais de poli -Si são usados principalmente em células solares devido ao seu baixo custo. Aqui, as zonas de sensibilidade aos comprimentos de onda da luz solar devem ser expandidas para aumentar a eficiência de engenharia das células solares. Filmes semicondutores compostos do Grupo IV, por exemplo, filmes de Si (Ge) dopados com átomos de C, Ge (C, Si) e/ou Sn com teores de vários %, em um substrato de Si ou Ge, foram identificados como possíveis soluções para este problema técnico problema. Neste estudo, calculamos a energia de formação de cada configuração atômica dos átomos de C, Ge e Sn no Si usando a teoria do funcional da densidade. O método "Hakoniwa" proposto por Kamiyama et al. [Materials Science in Semiconductor Processing, 43, 209 (2016)] foi aplicado a uma supercélula de 64 átomos de Si incluindo até três átomos de C, Ge e/ou Sn (até 4,56%) para obter a razão de cada configuração atômica e o valor médio dos bandgaps de Si. Não apenas a aproximação de gradiente gener...

consulte Mais informaçãoA ligação wafer de GaAs usando um tratamento de sulfeto de amônio (NH4)2S é investigada para várias estruturas. O efeito do ângulo de corte do wafer na condutividade elétrica de dispositivos de células solares III-V usando estruturas de wafer-bonded n-GaAs/n-GaAs é estudado. A difração de raios X de alta resolução é usada para confirmar a orientação errada das amostras ligadas. Além disso, comparamos as propriedades elétricas de junções pn epitaxialmente cultivadas em GaAs com estruturas ligadas a n-GaAs/p-GaAs. Microscopia eletrônica de transmissão de alta resolução (HRTEM) e microscopia eletrônica de transmissão de varredura(STEM) são usados para comparar a morfologia da interface em toda a gama de desorientações relativas após um RTP de 600 {sinal de grau}C. A proporção de regiões cristalinas bem ligadas para inclusões de óxido amorfo é consistente em todas as amostras ligadas, indicando que o grau de desorientação não afeta o nível de recristalização da interface em altas tempera...

consulte Mais informaçãoA transmissão óptica, a dependência da temperatura da fotoluminescência (PL) e o espalhamento Raman de SiC poroso preparado a partir do tipo p 6H-SiC são comparados com os do tipo p a granel 6H - SiC. Enquanto o espectro de transmissão do SiC a granel à temperatura ambiente revela uma borda relativamente nítida correspondente ao seu intervalo de banda em 3,03 eV, a borda de transmissão do SiC poroso (PSC) é muito ampla para determinar seu intervalo de banda. Acredita-se que essa borda larga pode ser devido a estados de superfície em PSC. À temperatura ambiente, o PL do PSC é 20 vezes mais forte do que o do SiC a granel. O espectro PL PSC é essencialmente independente da temperatura. As intensidades relativas dos picos de espalhamento Raman do PSC são amplamente independentes da configuração de polarização, em contraste com aquelas do SiC a granel, o que sugere que a ordem local é bastante aleatória. Fonte: IOPscience Para obter mais informações, visite nosso site: www.semic...

consulte Mais informaçãoA transmissão óptica, a dependência da temperatura da fotoluminescência (PL) e o espalhamento Raman de SiC poroso preparado a partir do tipo p 6H-SiC são comparados com os do tipo p a granel 6H - SiC. Enquanto o espectro de transmissão do SiC a granel à temperatura ambiente revela uma borda relativamente nítida correspondente ao seu intervalo de banda em 3,03 eV, a borda de transmissão do SiC poroso (PSC) é muito ampla para determinar seu intervalo de banda. Acredita-se que essa borda larga pode ser devido a estados de superfície em PSC. À temperatura ambiente, o PL do PSC é 20 vezes mais forte do que o do SiC a granel. O espectro PL PSC é essencialmente independente da temperatura. As intensidades relativas dos picos de espalhamento Raman do PSC são amplamente independentes da configuração de polarização, em contraste com aquelas do SiC a granel, o que sugere que a ordem local é bastante aleatória. Fonte: IOPscience Para obter mais informações, visite nosso site: www.semic...

consulte Mais informaçãoUm método para o recozimento de um cristal CdZnTe é descrito neste artigo. Os metais Cd e Zn puros são usados como fontes de recozimento, que simultaneamente fornecem pressões parciais de equilíbrio exatas de Cd e Zn para CdZnTe a uma determinada temperatura. As caracterizações revelam que a homogeneidade é altamente melhorada e as densidades de defeitos são diminuídas em mais de uma ordem, e assim as propriedades estruturais, ópticas e elétricas do cristal de CdZnTe são evidentemente melhoradas por este recozimento. A investigação da dependência da temperatura da qualidade do CdZnTe após o recozimento mostra que 1073 K é a temperatura de recozimento preferível para o CdZnTe. Este processo de recozimento já demonstrou ser superior ao recozimento de pressão parcial de equilíbrio aproximado usando Cd 1− y Zny liga como a fonte de recozimento. Fonte: IOPscience Para obter mais informações, visite nosso site: www.semiconductorwafers.net , envie-nos um e-mail para sales@powerwaywafe...

consulte Mais informaçãoNeste estudo, uma camada de InP foi transferida para um substrato de Sirevestido com um óxido térmico, através de um processo que combina o processo de corte iônico e ataque químico seletivo. Comparado com o corte iônico convencional de wafers de InP a granel, este esquema de transferência de camada não apenas aproveita o corte iônico ao salvar os substratos restantes para reutilização, mas também aproveita a corrosão seletiva para melhorar as condições da superfície transferida sem usar produtos químicos e mecânicos polimento. Uma heteroestrutura InP/InGaAs/InP inicialmente cultivada por MOCVD foi implantada com íons H+. A heteroestrutura implantada foi ligada a um wafer de Si revestido com uma camada térmica de SiO2. Após o recozimento subsequente, a estrutura ligada esfoliada na profundidade em torno da faixa projetada de hidrogênio localizada no substrato InP. A microscopia de força atômica mostrou que, após ataques químicos seletivos na estrutura conforme transferida, Fonte: IOPsc...

consulte Mais informaçãoRevisamos nossos esforços recentes no desenvolvimento de materiais infravermelhos HgCdSe em GaSbsubstratos via epitaxia de feixe molecular (MBE) para a fabricação de detectores infravermelhos de próxima geração com recursos de menor custo de produção e maior tamanho de formato de matriz de plano focal. A fim de obter epicamadas HgCdSe de alta qualidade, as camadas tampão ZnTe são cultivadas antes do crescimento de HgCdSe, e o estudo da tensão desajustada nas camadas tampão ZnTe mostra que a espessura da camada tampão ZnTe precisa estar abaixo de 300 nm para minimizar a geração de deslocamentos desajustados. A composição de liga/comprimento de comprimento de onda de corte de materiais HgCdSe pode variar em uma ampla faixa, variando a razão da pressão equivalente do feixe de Se/Cd durante o crescimento de HgCdSe. A temperatura de crescimento apresenta um impacto significativo na qualidade do material de HgCdSe, e uma temperatura de crescimento mais baixa leva a uma maior qualidade do mat...

consulte Mais informaçãoA corrosão úmida é uma etapa importante na fabricação de semicondutores e wafers solares e para a produção de dispositivos MEMS. Embora tenha sido substituído pela tecnologia de gravação a seco mais precisa na fabricação de dispositivos semicondutores avançados, ainda desempenha um papel importante na fabricação do próprio substrato de silício. Também é usado para fornecer alívio de tensão e texturização de superfície de wafers solares em alto volume. A tecnologia de silício de corrosão úmida para semicondutores e aplicações solares será revisada. Impacto nesta etapa para waferpropriedades e parâmetros críticos (planicidade, topologia e rugosidade da superfície para wafers semicondutores, textura da superfície e refletância para wafers solares) serão apresentados. A justificativa para o uso de uma tecnologia de corrosão e ácido para aplicações específicas na fabricação de semicondutores e wafers solares será apresentada. Fonte: IOPscience Para obter mais informações, visite nosso site:...

consulte Mais informaçãoFilmes homoepitaxiais de 4H-SiC foram cultivados em faces porosas de 4H-SiC (0001) fora do eixo 8° na faixa de temperatura por deposição de vapor químico a partir do precursor bis(trimetilsilil)metano (BTMSM). A energia de ativação para o crescimento foi de 5,6 kcal/mol, indicando que o crescimento do filme é dominado pelo mecanismo de difusão limitada. Falhas de empilhamento triangulares foram incorporadas no filme fino de SiC crescido em baixa temperatura de 1280°C devido à formação do politipo 3C-SiC. Além disso, deslocamentos super-parafusos apareceram seriamente no filme de SiC crescido abaixo de 1320°C. Morfologia limpa e sem características foi observada no filme SiC crescido abaixo de 25 centímetros cúbicos padrão por minuto (sccm) taxa de fluxo de gás de arraste de BTMSM a 1380°C, enquanto o politipo 3C-SiC com limites de posicionamento duplo cresceu a taxa de fluxo de 30 sccm de BTMSM. A densidade de deslocamento da camada epi foi fortemente influenciad...

consulte Mais informaçãoDurante a última década, o uso de camadas e estruturas monocristalinas de germânio (Ge) em combinação com substratos de silício (Si) levou a um renascimento da pesquisa de defeitos em Ge. Em cristais de Si, dopantes e tensões afetam os parâmetros de defeito pontual intrínseco (vacância V e auto-intersticial I ) e assim alteram as concentrações de equilíbrio térmico de V e I . No entanto, o controle das concentrações de defeitos pontuais intrínsecos ainda não foi realizado no mesmo nível em cristais de Ge e em cristais de Si devido à falta de dados experimentais. Neste estudo, usamos cálculos da teoria funcional da densidade (DFT) para avaliar o efeito da tensão isotrópica interna/externa ( σin / σ ex ) sobre a entalpia de formação ( H f ) dos neutros V e I em torno do átomo dopante (B, Ga, C, Sn e Sb) em Ge e comparou os resultados com os de Si. Os resultados da análise são triplos. Primeiro, H f de V ( I ) em Ge perfeito é diminuído (aumentado) por σ compressivo em enquanto H f de V (...

consulte Mais informaçãoWafer Foundry: 26321#, Liamei Rd. Lianhua Industrial Area, Tong an, Xiamen 361100, China

informações de contato

informações de contato luna@powerwaywafer.com

luna@powerwaywafer.com powerwaymaterial@gmail.com

powerwaymaterial@gmail.com  +86-592-5601 404

+86-592-5601 404